In mechanics, the flexural modulus or bending modulus [1] is an intensive property that is computed as the ratio of stress to strain in flexural deformation, or the tendency for a material to resist bending. It is determined from the slope of a stress-strain curve produced by a flexural test (such as the ASTM D790), and uses units of force per area. [2] The flexural modulus defined using the 2-point (cantilever) and 3-point bend tests assumes a linear stress strain response. [3]

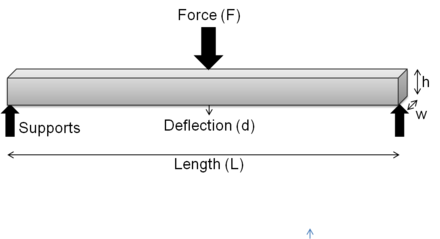

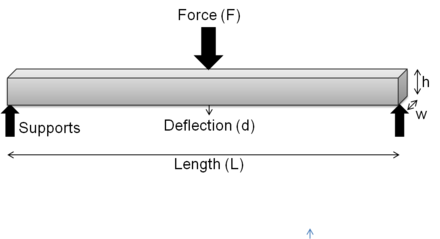

For a 3-point test of a rectangular beam behaving as an isotropic linear material, where w and h are the width and height of the beam, I is the second moment of area of the beam's cross-section, L is the distance between the two outer supports, and d is the deflection due to the load F applied at the middle of the beam, the flexural modulus: [1]

From elastic beam theory

and for rectangular beam

thus ( Elastic modulus)

For very small strains in isotropic materials – like glass, metal or polymer – flexural or bending modulus of elasticity is equivalent to the tensile modulus ( Young's modulus) or compressive modulus of elasticity. However, in anisotropic materials, for example wood, these values may not be equivalent. Moreover, composite materials like fiber-reinforced polymers [4] [3] or biological tissues [5] are inhomogeneous combinations of two or more materials, each with different material properties, therefore their tensile, compressive, and flexural moduli usually are not equivalent.

Related pages

References

- ^ a b Zweben, C.; W. S. Smith & M. W. Wardle (1979), "Test methods for fiber tensile strength, composite flexural modulus, and properties of fabric-reinforced laminates", Composite Materials: Testing and Design (Fifth Conference), ASTM International: 228–228–35, doi: 10.1520/STP36912S, ISBN 978-0-8031-4495-8

- ^ D790-03: Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials, West Conshohocken, PA: ASTM International, 2003

- ^

a

b Askeland, Donald R. (2016).

The science and engineering of materials. Wright, Wendelin J. (Seventh ed.). Boston, MA. p. 200.

ISBN

978-1-305-07676-1.

OCLC

903959750.

{{ cite book}}: CS1 maint: location missing publisher ( link) - ^ Tsai, S. W. (December 1979). Composite Materials, Testing and Design. ASTM. p. 247. ISBN 9780803103078.

- ^ Chahine, Nadeen O.; Wang, Christopher C-B.; Hung, Clark T.; Ateshian, Gerard A. (August 2004). "Anisotropic strain-dependent material properties of bovine articular cartilage in the transitional range from tension to compression". Journal of Biomechanics. 37 (8): 1251–1261. doi: 10.1016/j.jbiomech.2003.12.008. ISSN 0021-9290. PMC 2819725. PMID 15212931.

In mechanics, the flexural modulus or bending modulus [1] is an intensive property that is computed as the ratio of stress to strain in flexural deformation, or the tendency for a material to resist bending. It is determined from the slope of a stress-strain curve produced by a flexural test (such as the ASTM D790), and uses units of force per area. [2] The flexural modulus defined using the 2-point (cantilever) and 3-point bend tests assumes a linear stress strain response. [3]

For a 3-point test of a rectangular beam behaving as an isotropic linear material, where w and h are the width and height of the beam, I is the second moment of area of the beam's cross-section, L is the distance between the two outer supports, and d is the deflection due to the load F applied at the middle of the beam, the flexural modulus: [1]

From elastic beam theory

and for rectangular beam

thus ( Elastic modulus)

For very small strains in isotropic materials – like glass, metal or polymer – flexural or bending modulus of elasticity is equivalent to the tensile modulus ( Young's modulus) or compressive modulus of elasticity. However, in anisotropic materials, for example wood, these values may not be equivalent. Moreover, composite materials like fiber-reinforced polymers [4] [3] or biological tissues [5] are inhomogeneous combinations of two or more materials, each with different material properties, therefore their tensile, compressive, and flexural moduli usually are not equivalent.

Related pages

References

- ^ a b Zweben, C.; W. S. Smith & M. W. Wardle (1979), "Test methods for fiber tensile strength, composite flexural modulus, and properties of fabric-reinforced laminates", Composite Materials: Testing and Design (Fifth Conference), ASTM International: 228–228–35, doi: 10.1520/STP36912S, ISBN 978-0-8031-4495-8

- ^ D790-03: Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials, West Conshohocken, PA: ASTM International, 2003

- ^

a

b Askeland, Donald R. (2016).

The science and engineering of materials. Wright, Wendelin J. (Seventh ed.). Boston, MA. p. 200.

ISBN

978-1-305-07676-1.

OCLC

903959750.

{{ cite book}}: CS1 maint: location missing publisher ( link) - ^ Tsai, S. W. (December 1979). Composite Materials, Testing and Design. ASTM. p. 247. ISBN 9780803103078.

- ^ Chahine, Nadeen O.; Wang, Christopher C-B.; Hung, Clark T.; Ateshian, Gerard A. (August 2004). "Anisotropic strain-dependent material properties of bovine articular cartilage in the transitional range from tension to compression". Journal of Biomechanics. 37 (8): 1251–1261. doi: 10.1016/j.jbiomech.2003.12.008. ISSN 0021-9290. PMC 2819725. PMID 15212931.